Project Briefing

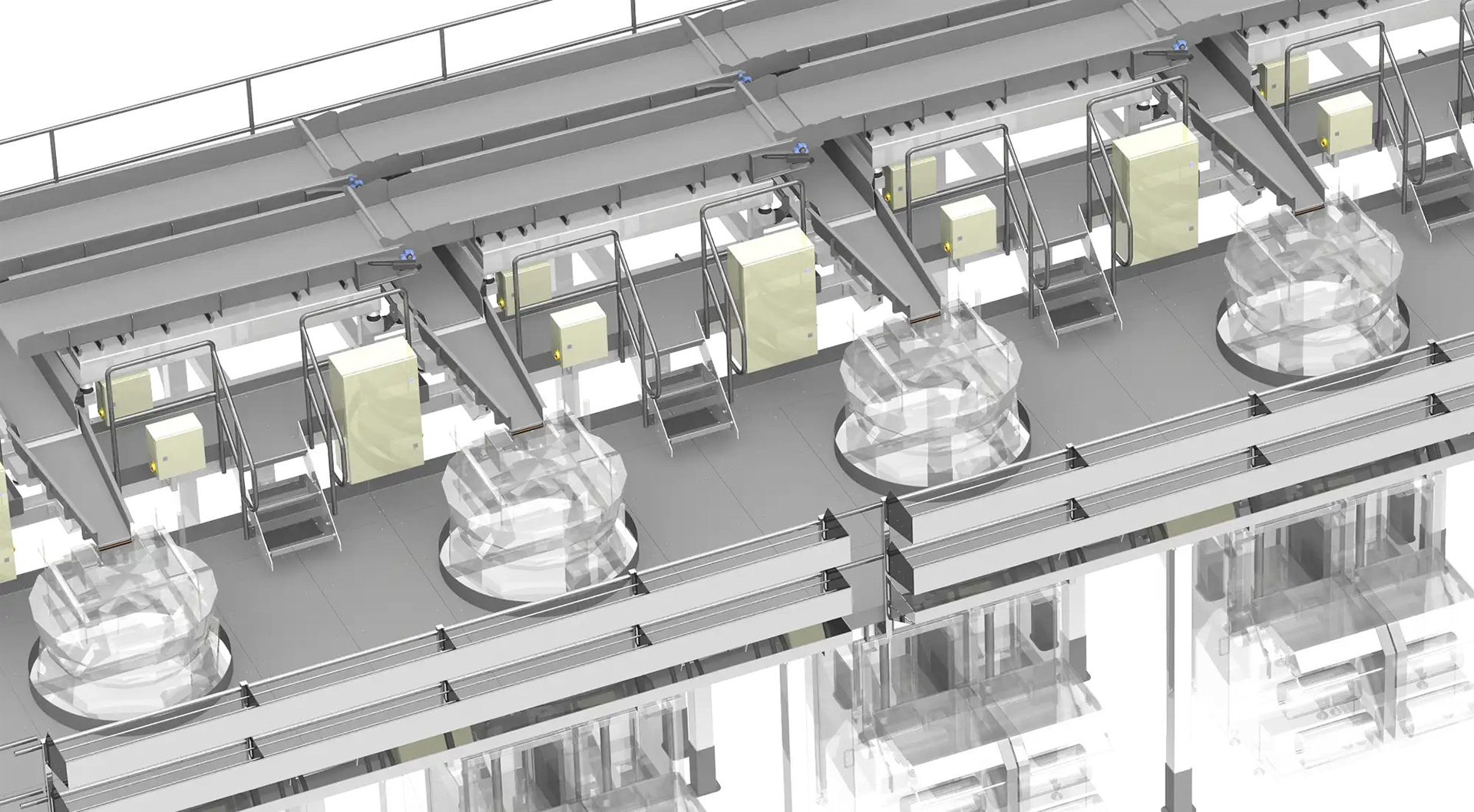

Structural design project of an industrial platform intended to host vibratory conveyors at the upper deck, three weighing scales at the lower deck and three vertical form fill seal machines (VFFS) at the ground level as part of the filling and packaging section at a cereal production line.

Overview

Project Description

Vertical form fill seal machines are commonly used in the packaging industry for food, and a wide variety of other products. They usually require two-level structures to be operating properly.

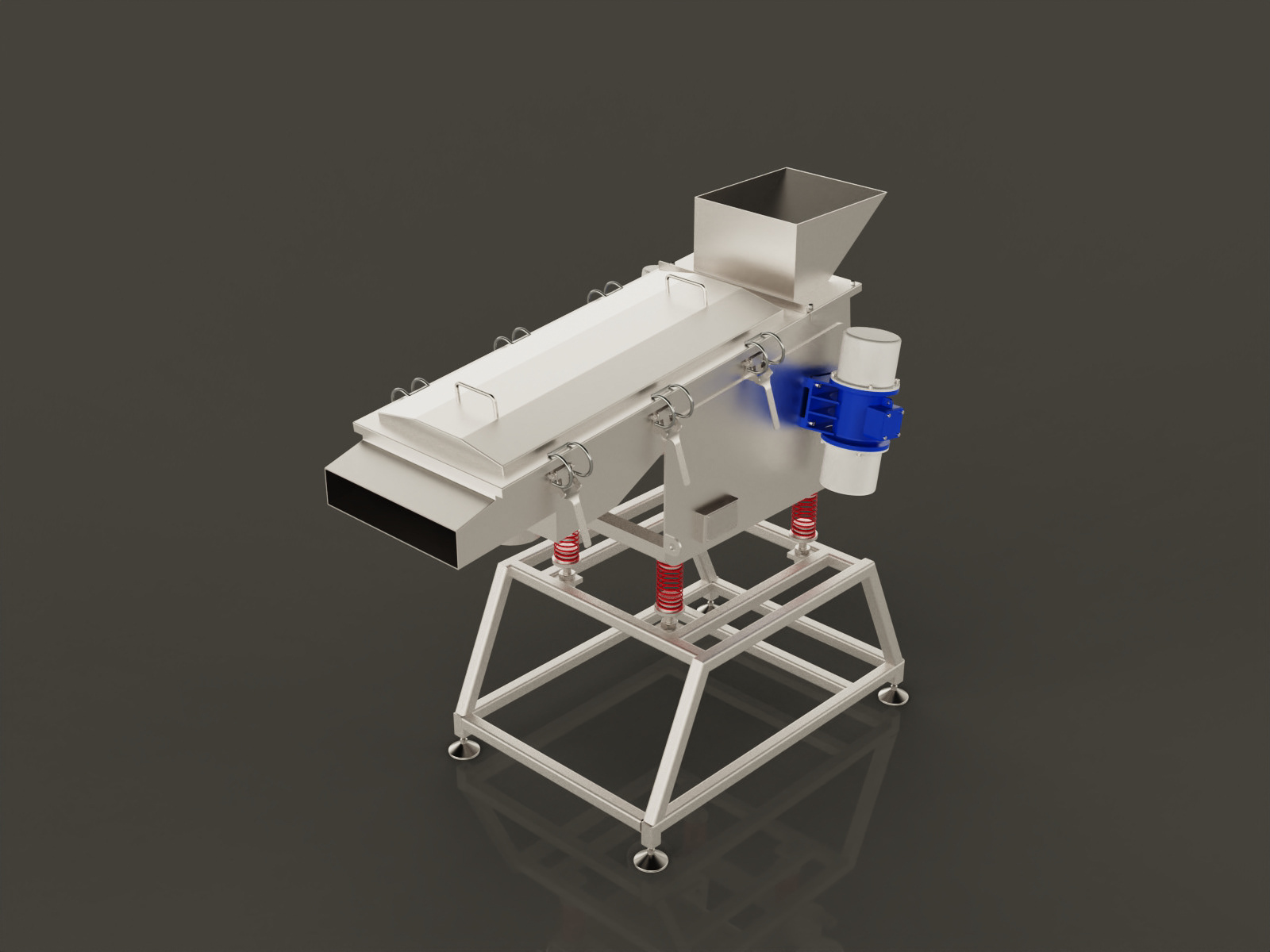

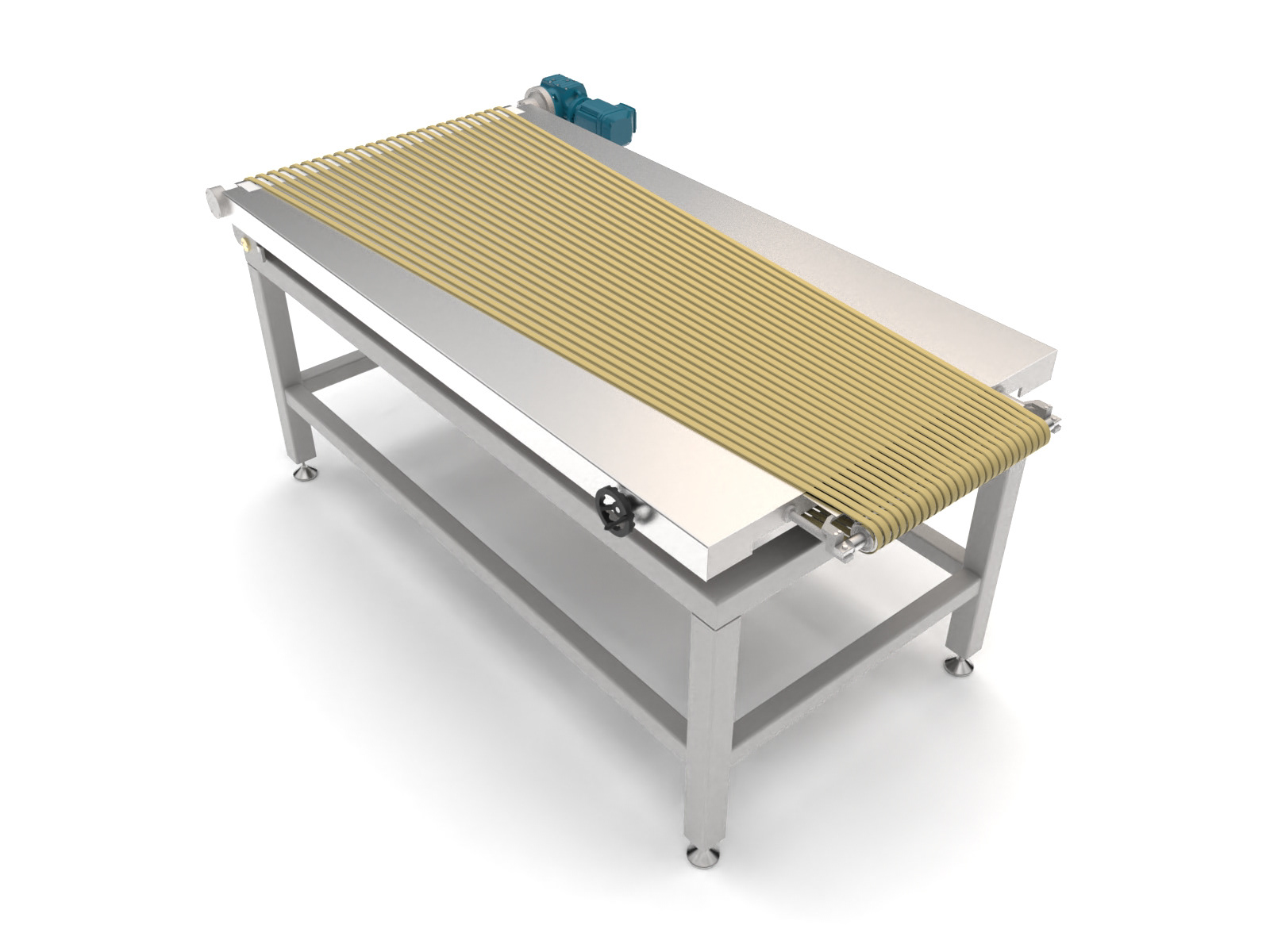

At the upper deck of the platform usually lie the conveying equipment - vibratory conveyors in the case of this project - that feed the weighing scales located at the lower deck with the products.

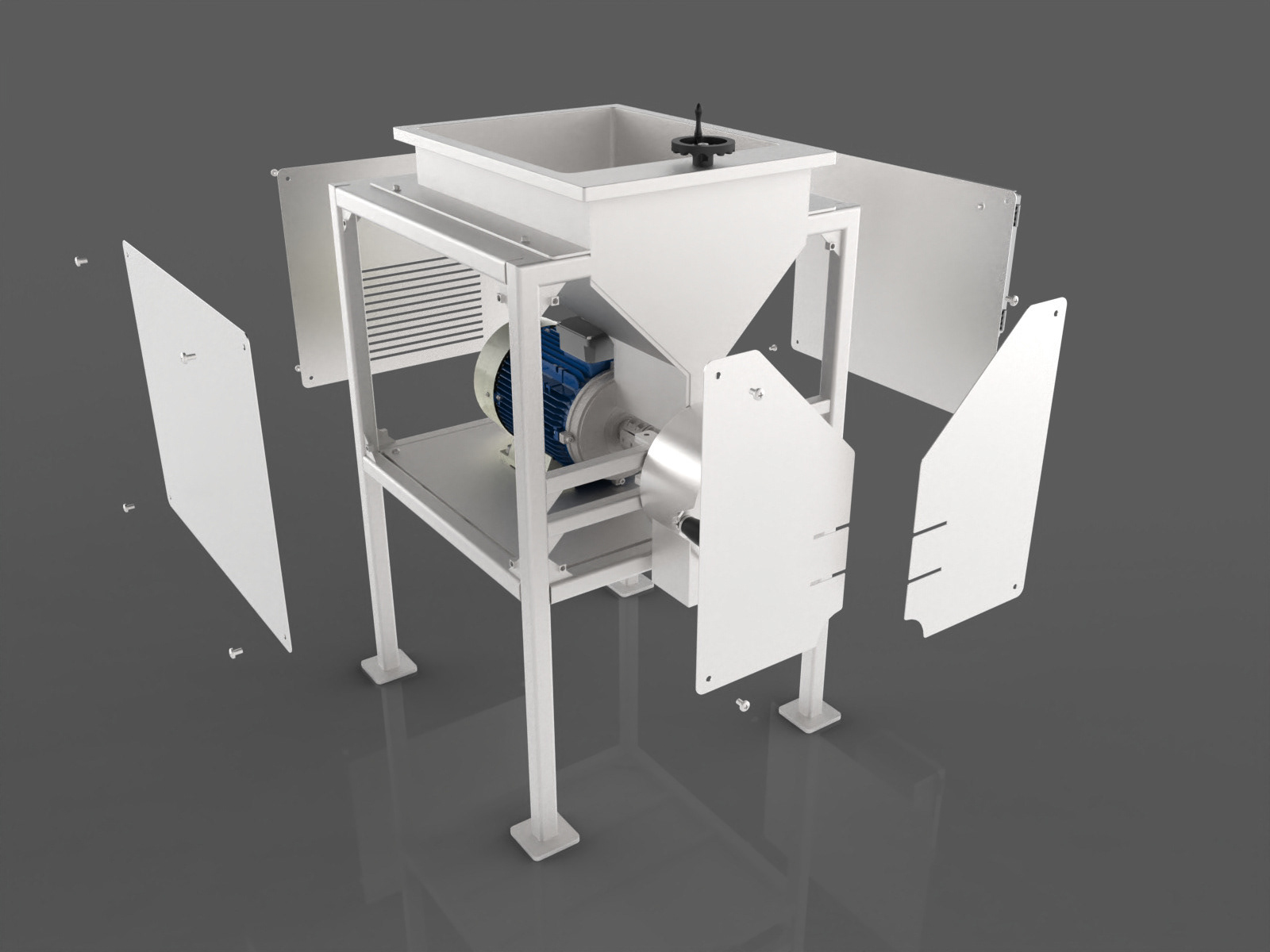

The weighing scales operating at high speed, continuously feed the vertical form fill machines located on the ground level with the products to be packaged at a desired target weight.

Overview Without Guardrails

Design Concept

The platform conceptual design was provided by the VFFS machines' OEM in order for the customer to design and construct the required platform using locally available resources and steel members.

Accordingly, the conceptual design was modified in a complete re-designing process in order for the platform to be perfectly located at the customer's facility and by using market available standard structural members.

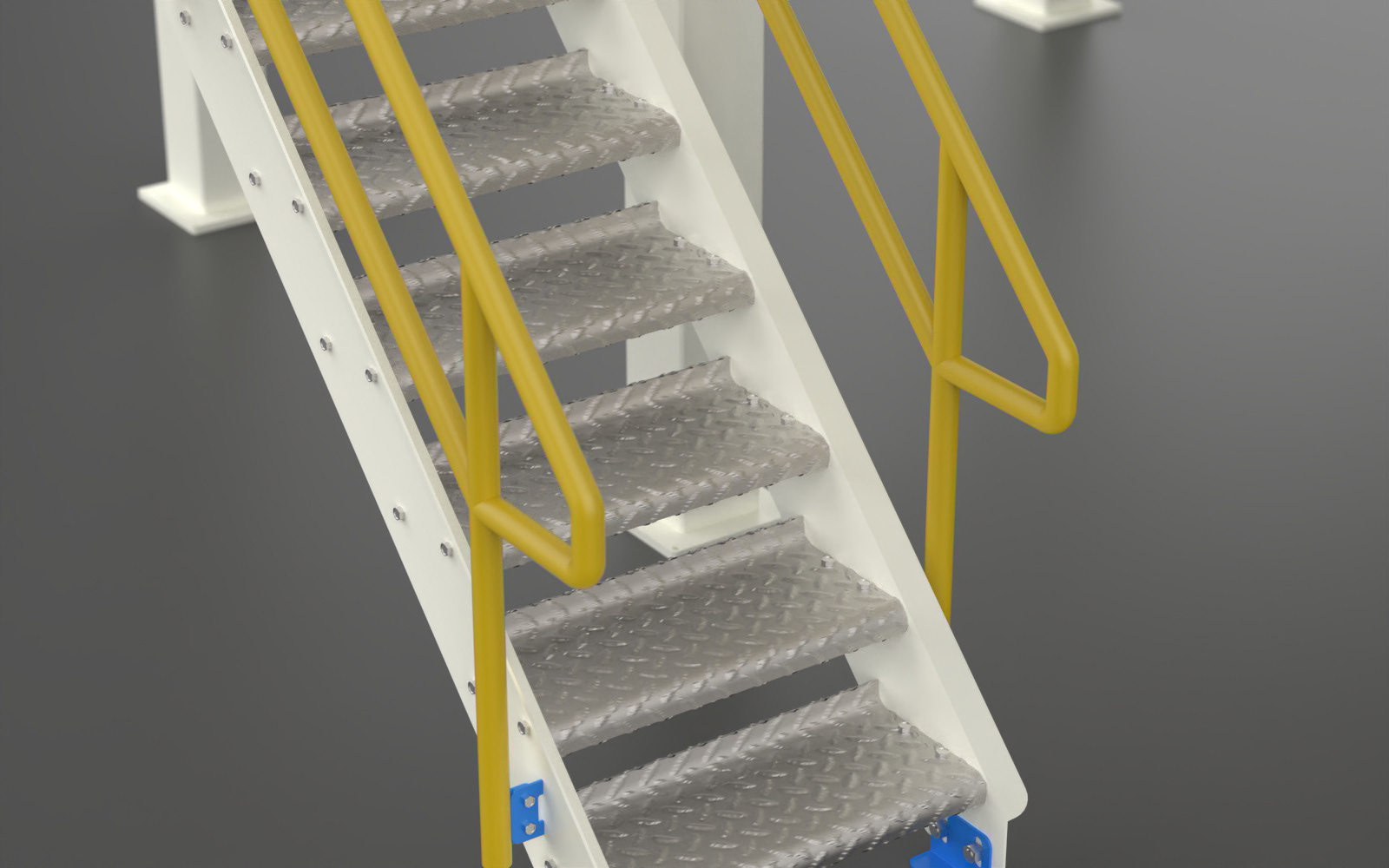

Stair Details

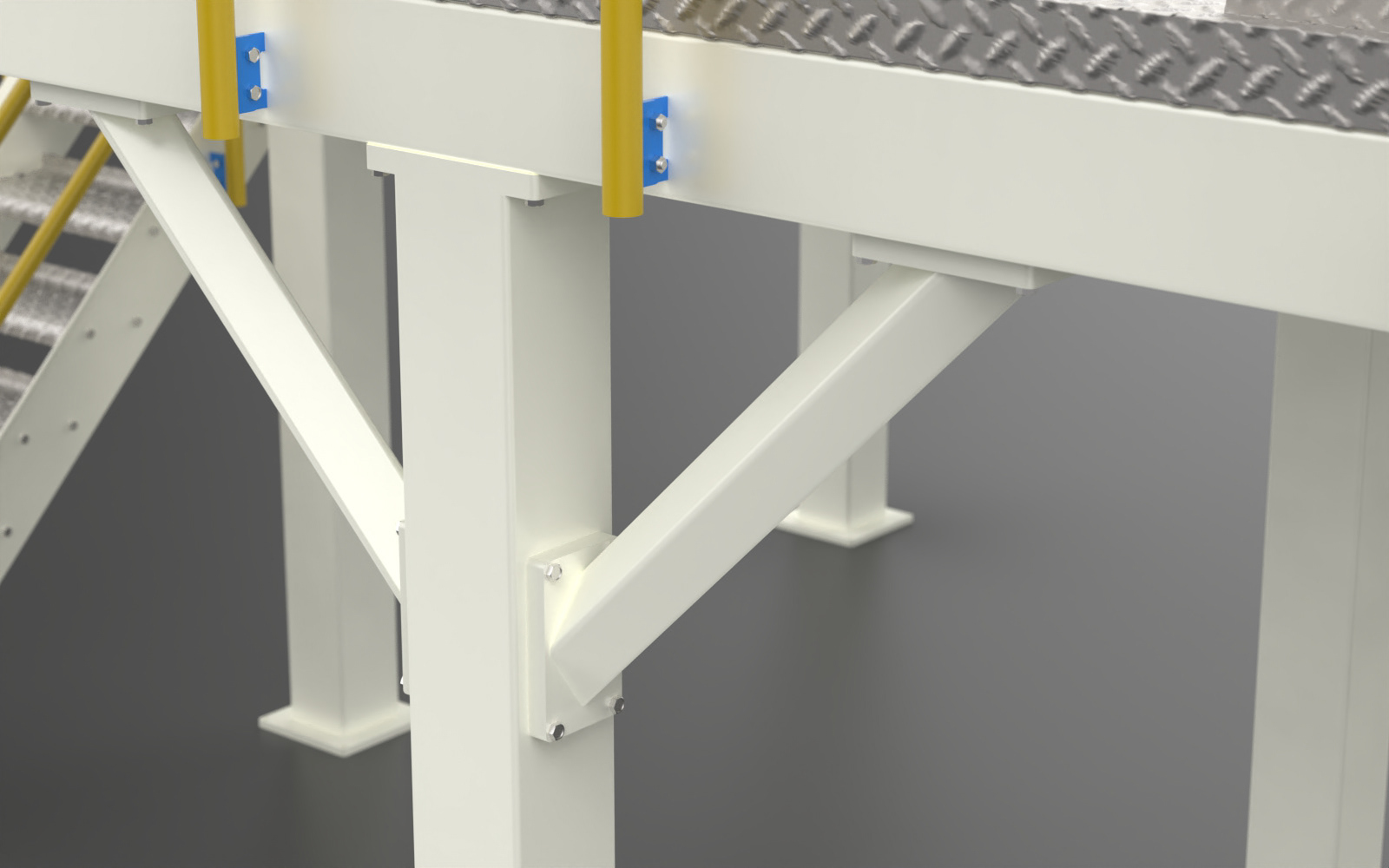

Rotated Bracket Members to Prevent Dust Buildup

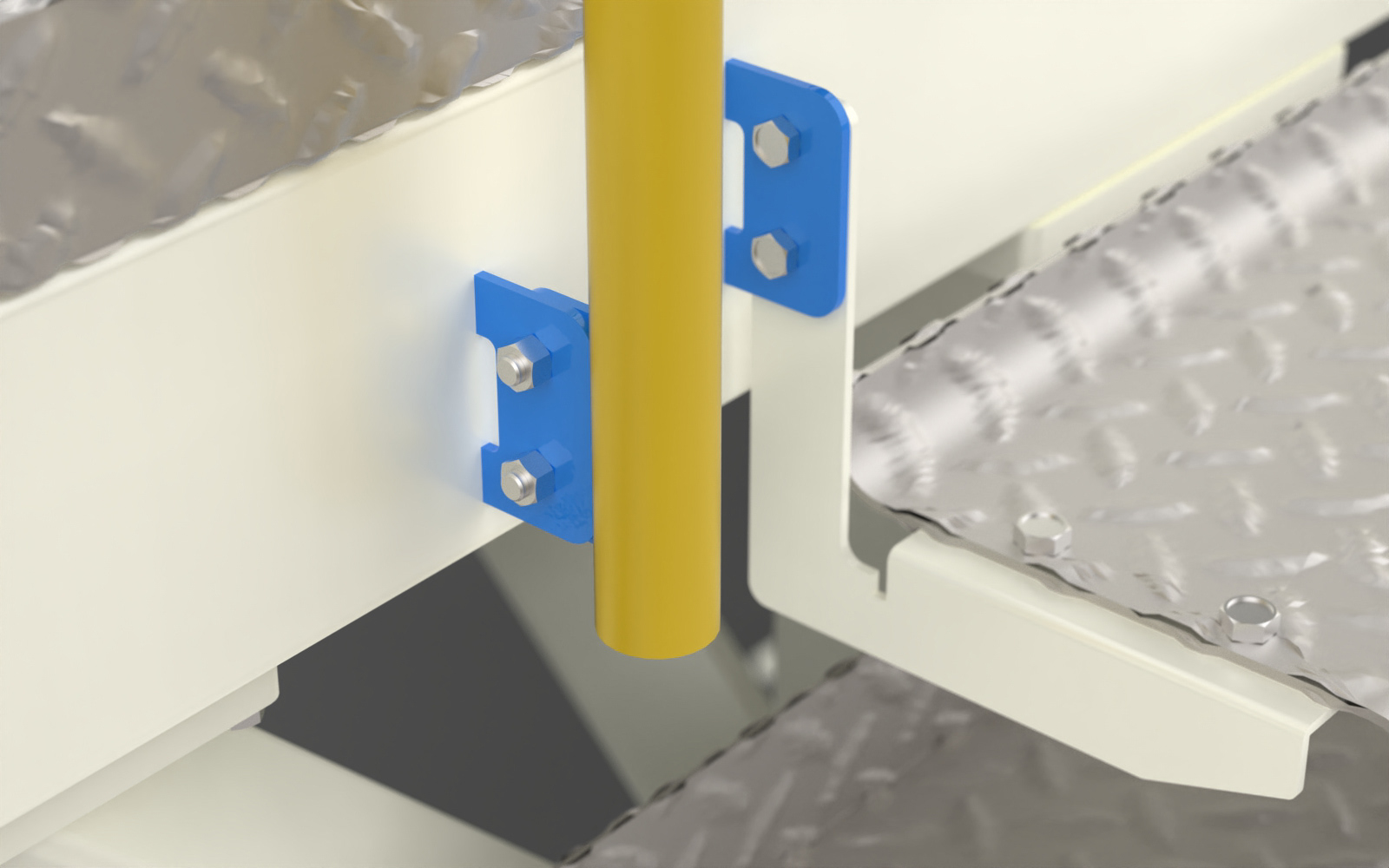

Upper to Lower Deck Step Details

Design Features

1. Platform designed to be dismantled when needed in less than a working day. For this reason, welding was only limited to the plates/flanges fixed to the structural members (columns & beams).

2. Most of the connecting plates are threaded in order to reduce the usage of nuts & washers for a firmer connection and better appeal.

3. Bracket members are designed in a rotated position to prevent dust buildup.

4. Stainless steel diamond plate (tread plate) is used as a non-skid material for gratings and steps.

5. Mild steel is used as the material for all the structural members.

6. All mild steel parts are coated and painted as an anti-corrosive protection.

Overview - Structural

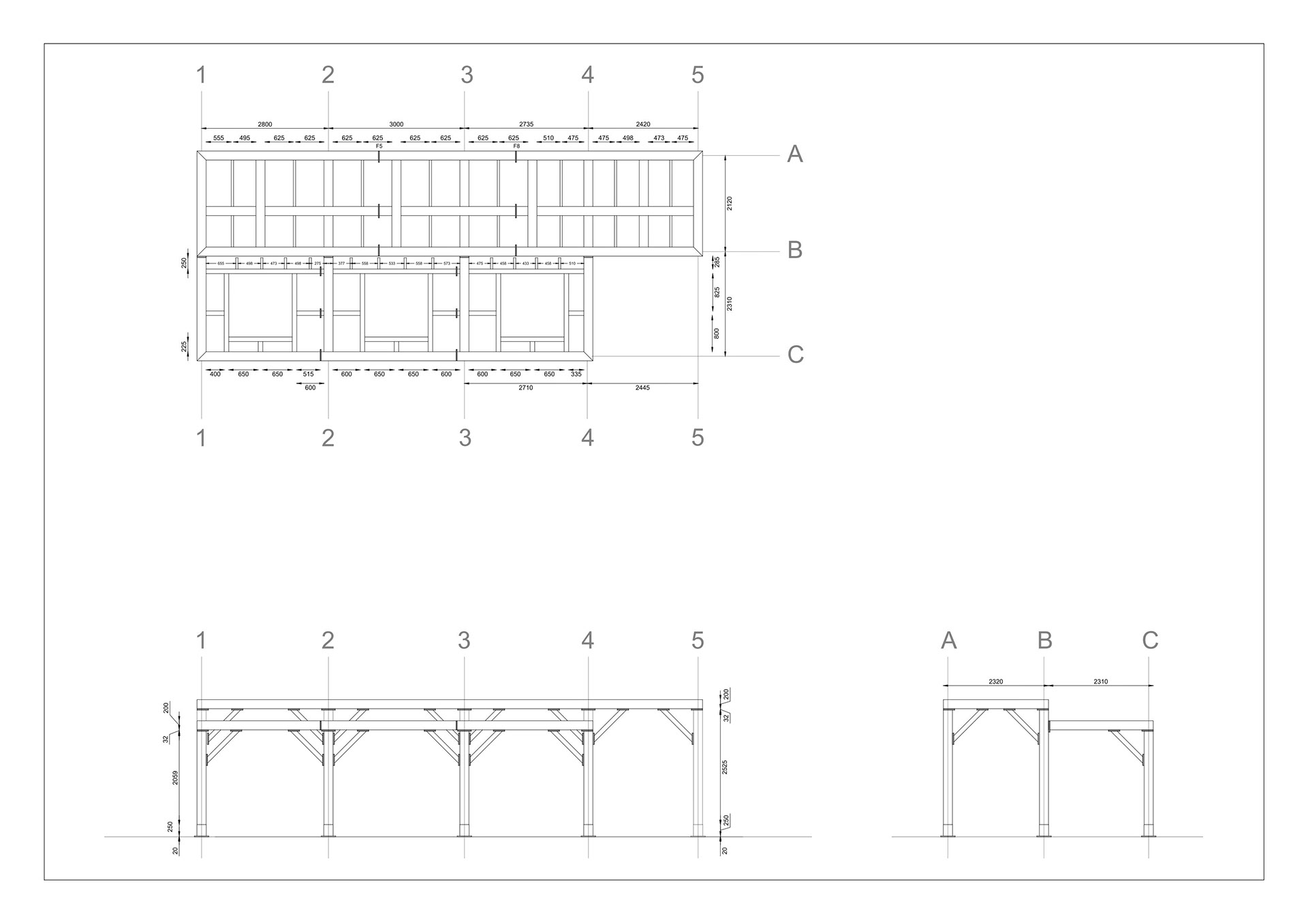

Project Plan & Elevation 2D Drawing

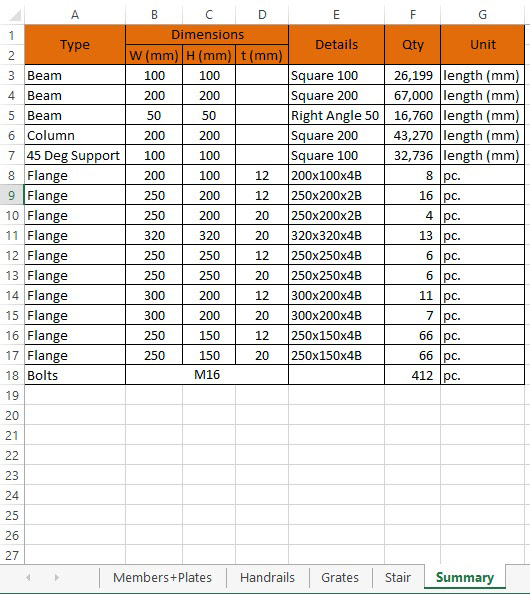

Project BOM

Typical Vibratory Conveyors Distribution - image from kmgsystems.com

Weighing Scale Mounted on VFFS Machine - image from tnasolutions.com

Important Notice

The original design is a property of the original equipment manufacturer (OEM). There is no intention behind this project to commercially produce or sell the products or the designs.

All published drawings and renders are properties of owners, developers or OEM and were published for professional record only.

Design files or renders shall not be distributed or used under any circumstances.