Project Description

Pulverizers, pulverizing machines or grinders are mechanical devices that grind coarse particles into fine particles.

This project is a product design of a pulverizing machine that grinds coarse sugar for an FMCG manufacturer of breakfast cereals.

The customer's aim is to locally manufacture the machine at a low cost, moreover the design must be optimized to meet the customer's budget as well as the available manufacturing resources and techniques.

The customer's aim is to locally manufacture the machine at a low cost, moreover the design must be optimized to meet the customer's budget as well as the available manufacturing resources and techniques.

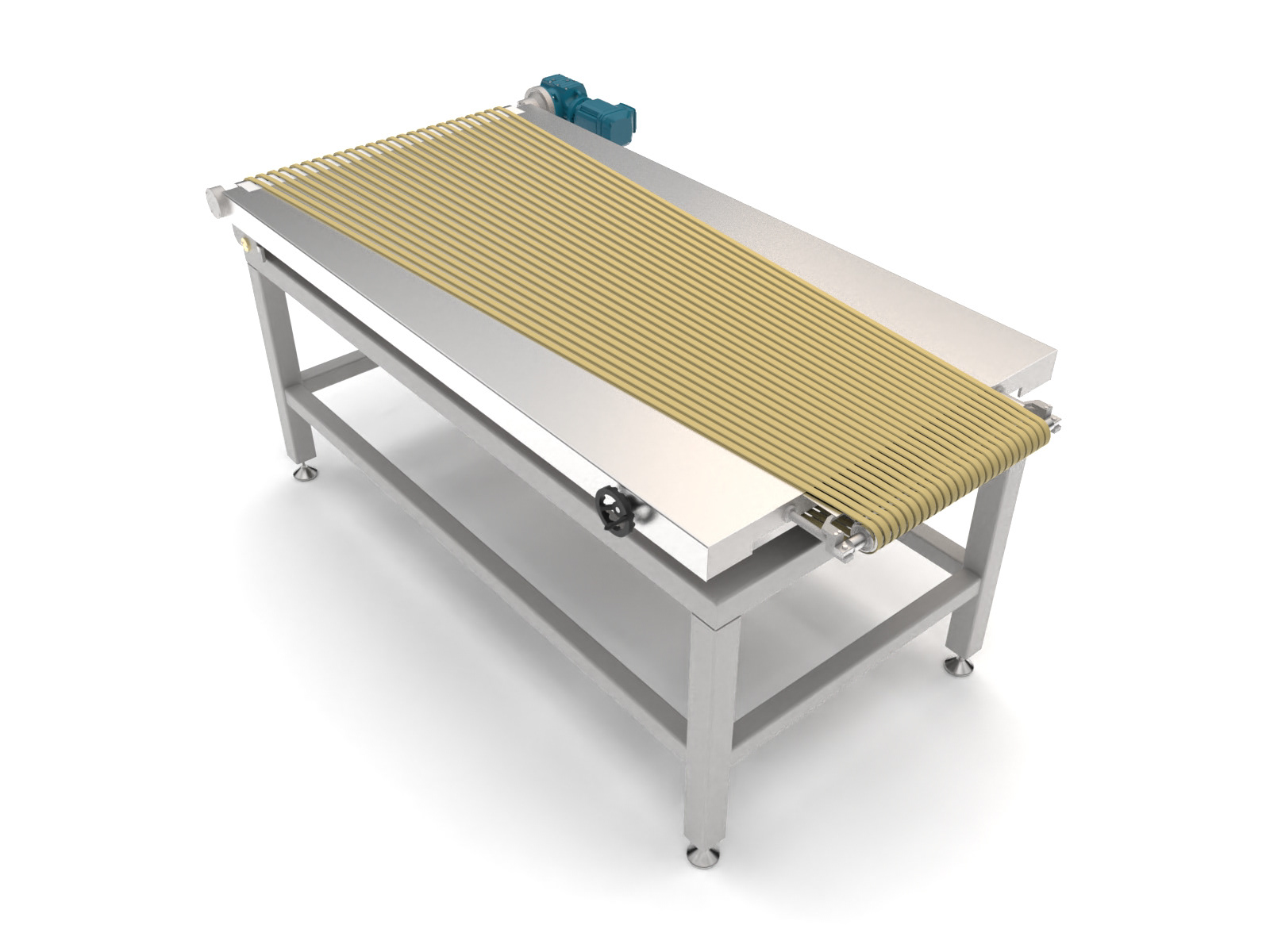

Sugar Pulverizing Machine - Overview 1

Design Features Required

In order to be matching the customer's requirements within available manufacturing resources, the design has to fulfill the following:

1. There should be no parts requiring die casting. Manufacturing and fabrication processes available are bending, turning, milling, laser cutting and welding.

2. Limited welding.

3. The inlet basin of coarse sugar must have a sharp angle to prevent sticking of particles and the need to install vibrators.

4. The flow of coarse sugar has to be controlled for a proper operation.

5. The motor must be controlled by a variable frequency drive (VFD), so the electrical enclosure must fit the VFD.

6. The grinding rotor design must be optimized to minimize air propulsion.

7. The user can change the fine particle's size by replacing the screen/mesh part.

2. Limited welding.

3. The inlet basin of coarse sugar must have a sharp angle to prevent sticking of particles and the need to install vibrators.

4. The flow of coarse sugar has to be controlled for a proper operation.

5. The motor must be controlled by a variable frequency drive (VFD), so the electrical enclosure must fit the VFD.

6. The grinding rotor design must be optimized to minimize air propulsion.

7. The user can change the fine particle's size by replacing the screen/mesh part.

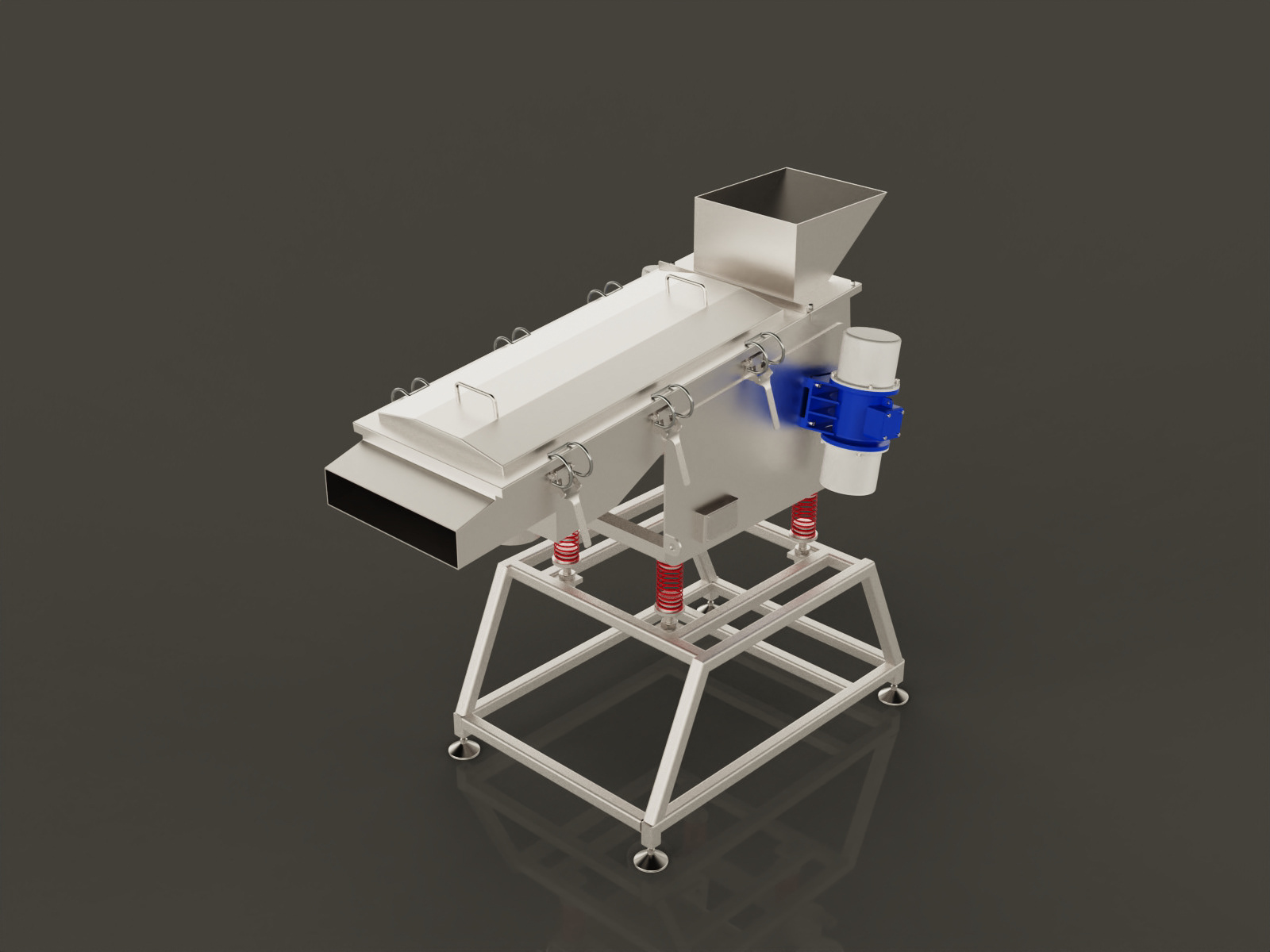

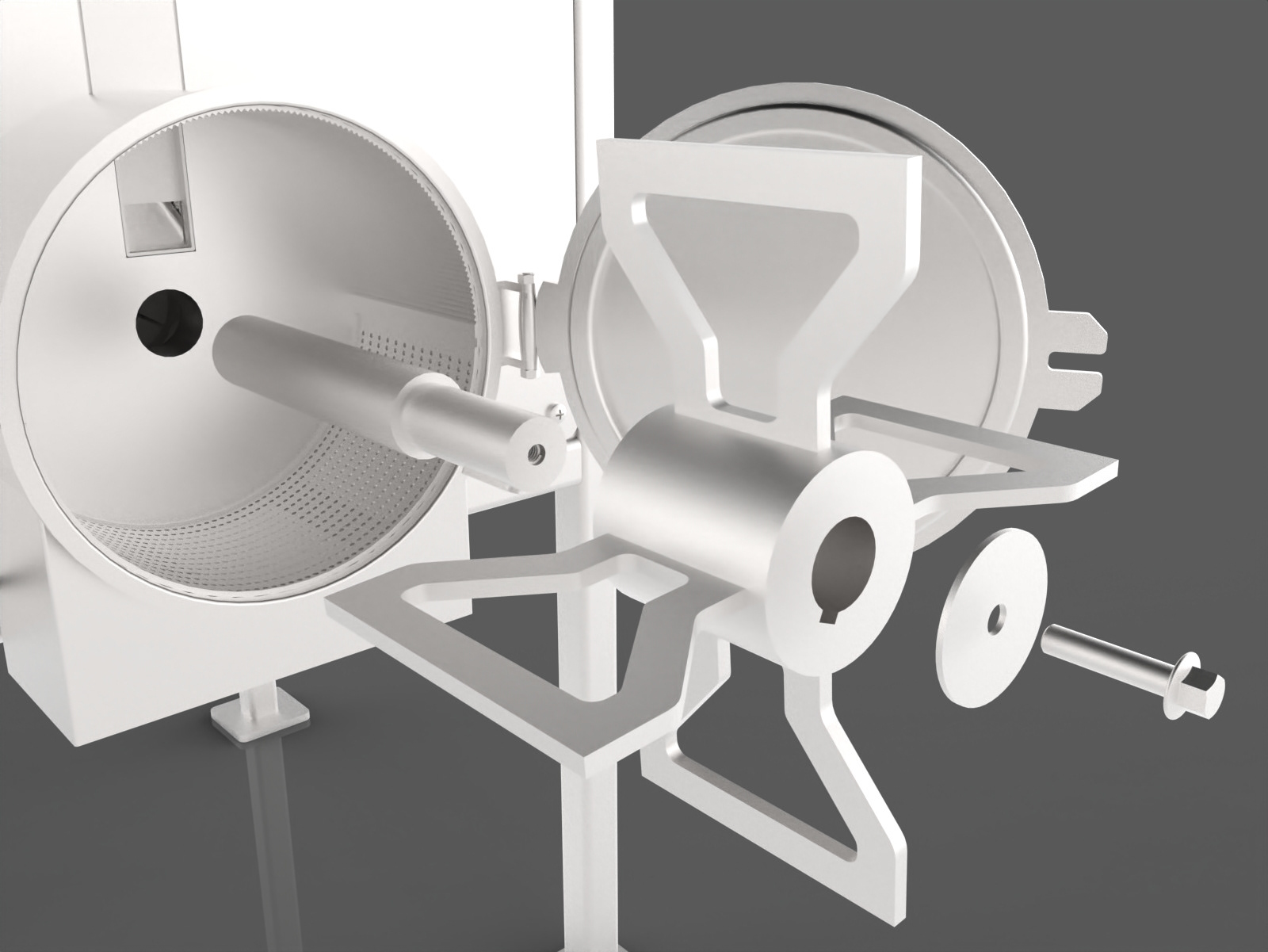

Sugar Pulverizing Machine - Exploded Overview

The Design

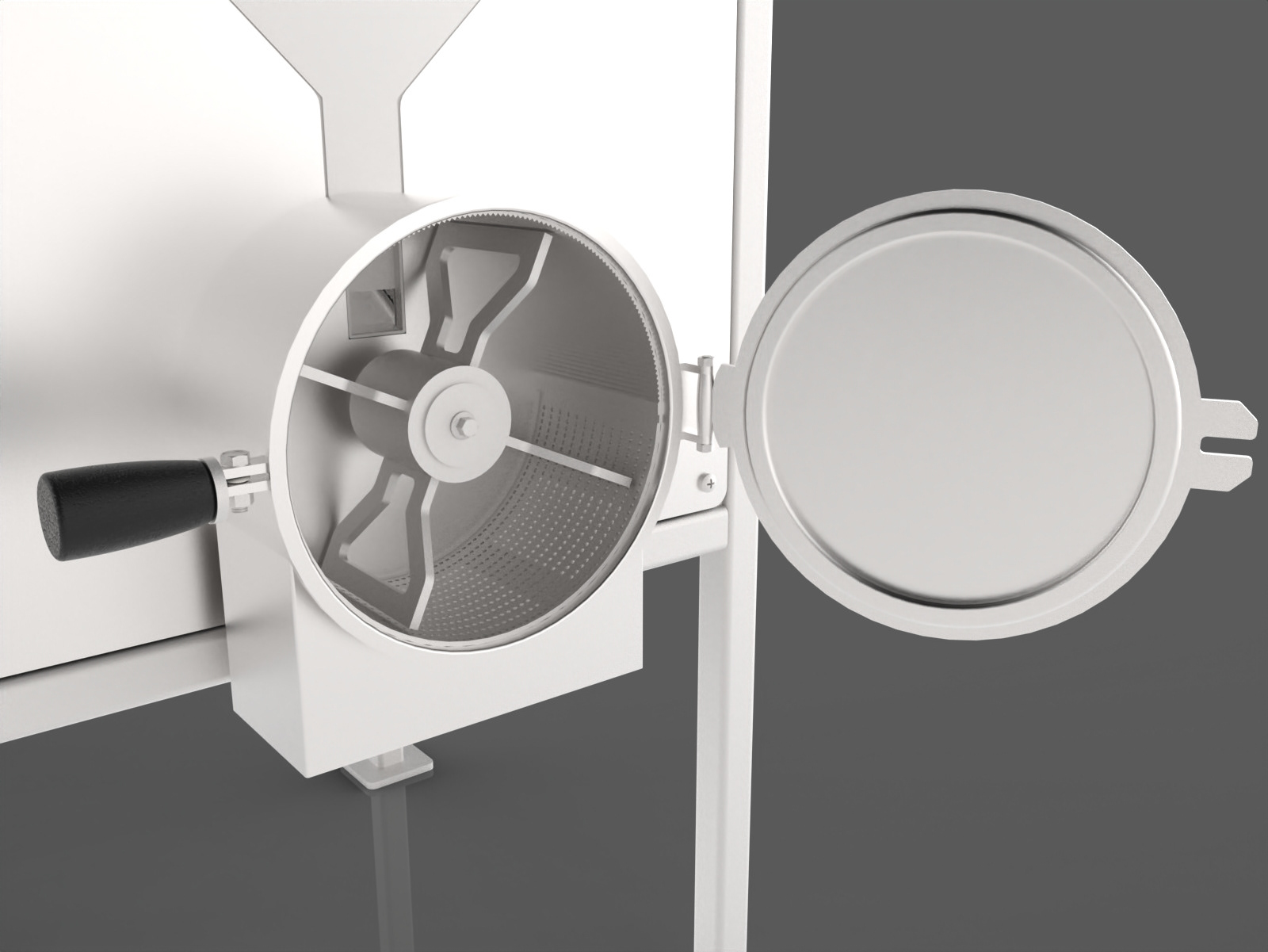

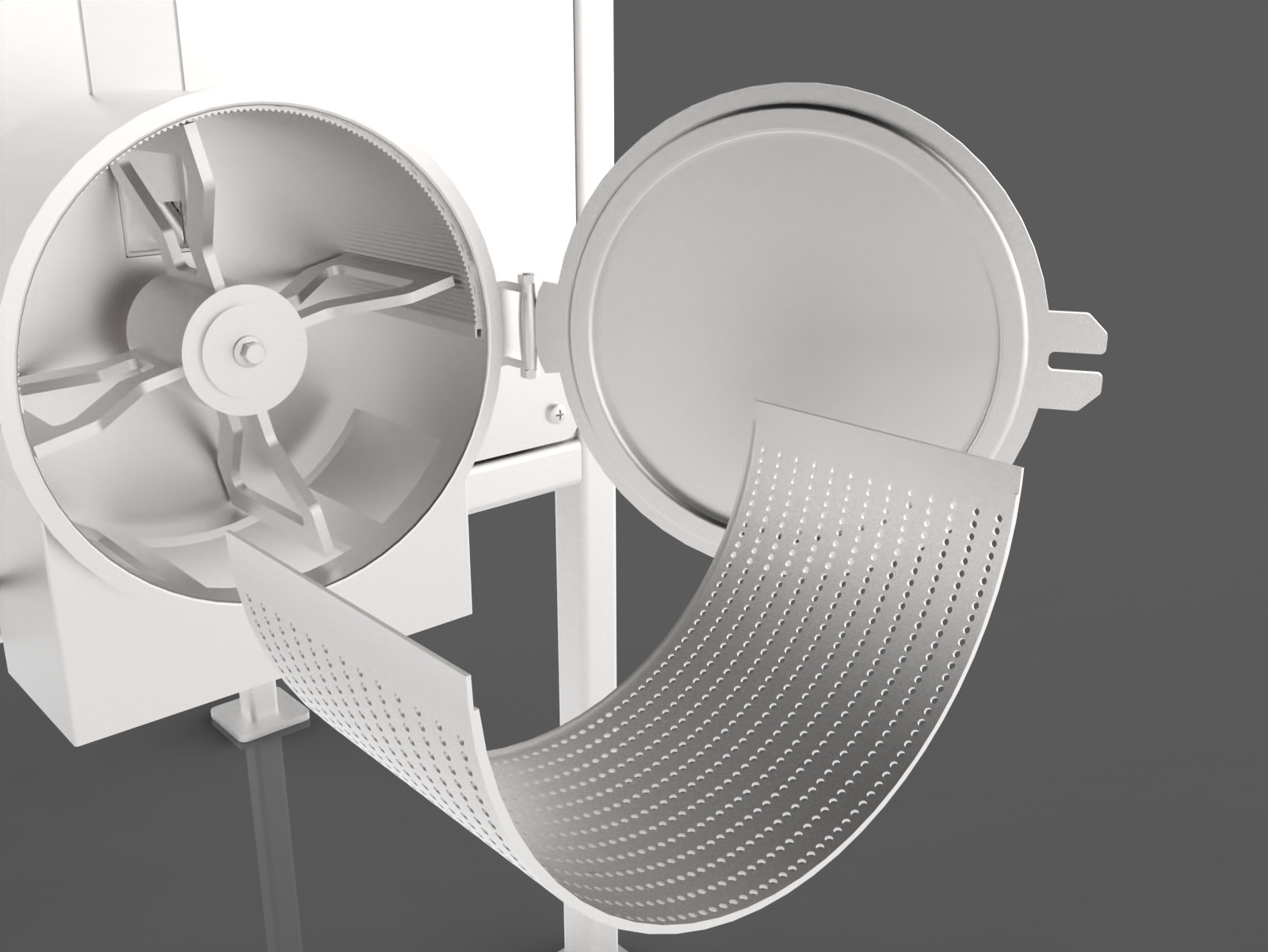

The rotor consists of a shaft hub with socketed screwed blades with interference fit. The blades are hollow to minimize air propulsion and output of flying sugar powder.

Easy to-open and to-clean rotor housing with simple closing system, interchangeable screen with different mesh sizes and a corrugated arc in the grinding area.

The Inlet basin is designed with sharp angles and a gate with adjustable shutter. The shutter mechanism is simple and consists of a handle and a screw fixed to the inlet basin.

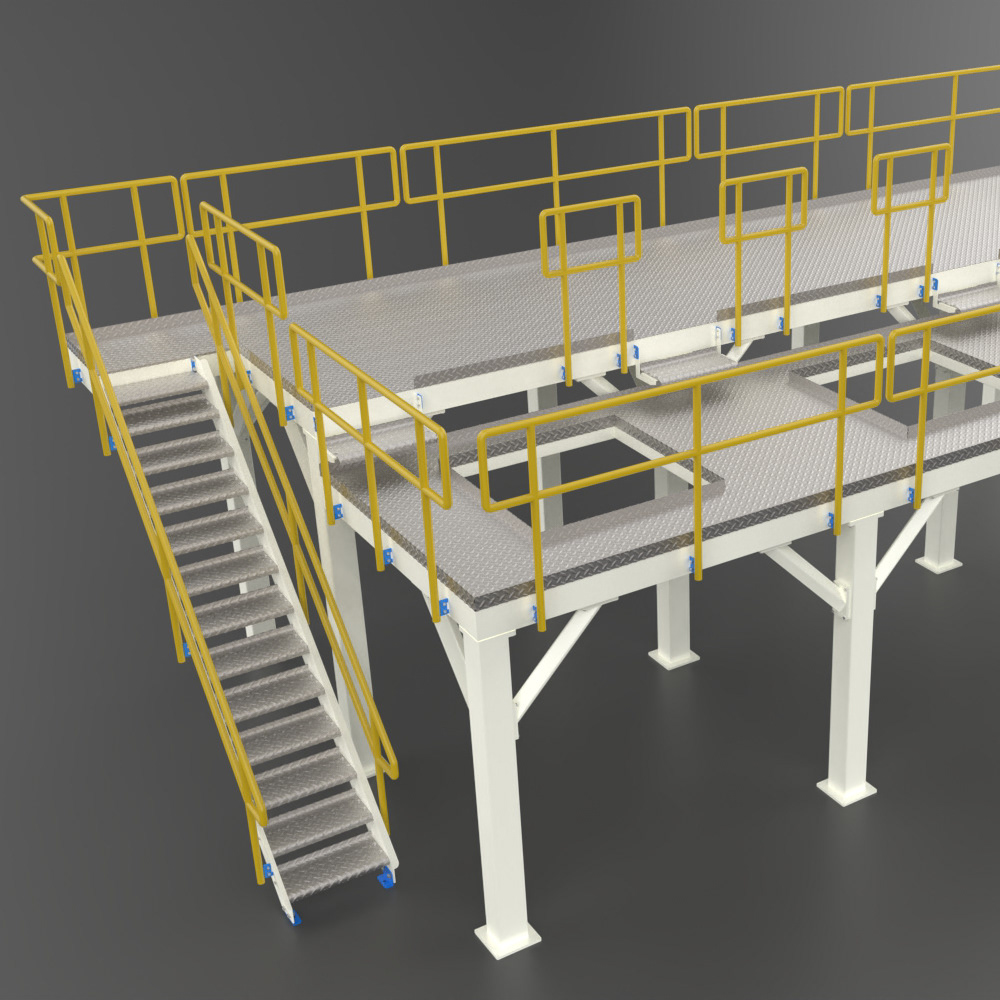

Simple structure design with screwed enclosure.

Selected materials for most parts are stainless steel 304 & 316 and limited selection for mild steel.

The design is modeled using SOLIDWORKS. The electric motor, the coupling and the shutter's handle are imported parts from online available 3D models.

Sugar Pulverizing Machine - Overview 2

Rotor Housing

Rotor Exploded View

Interchangeable Screen

Adjustable Coarse Sugar Flow

Important Notice

All published drawings, renders and animations are properties of owners, developers or OEM and were published for professional record only.

Design files or renders shall not be distributed or used under any circumstances.