System Description

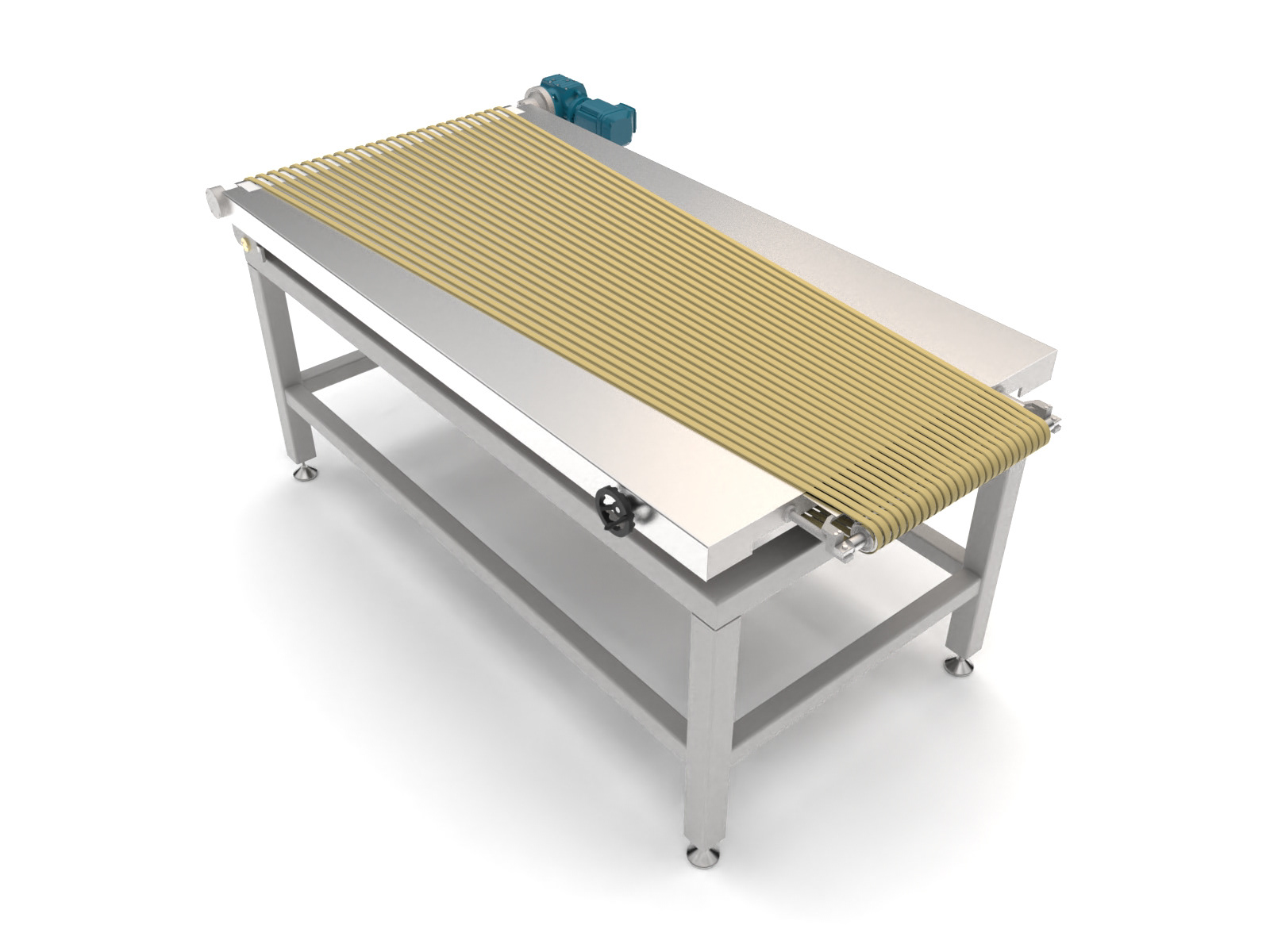

In food industries, sieving or screening applications are essential at many different production phases; from filtering of raw materials to screening products before coating or sieving product's debris before packaging.

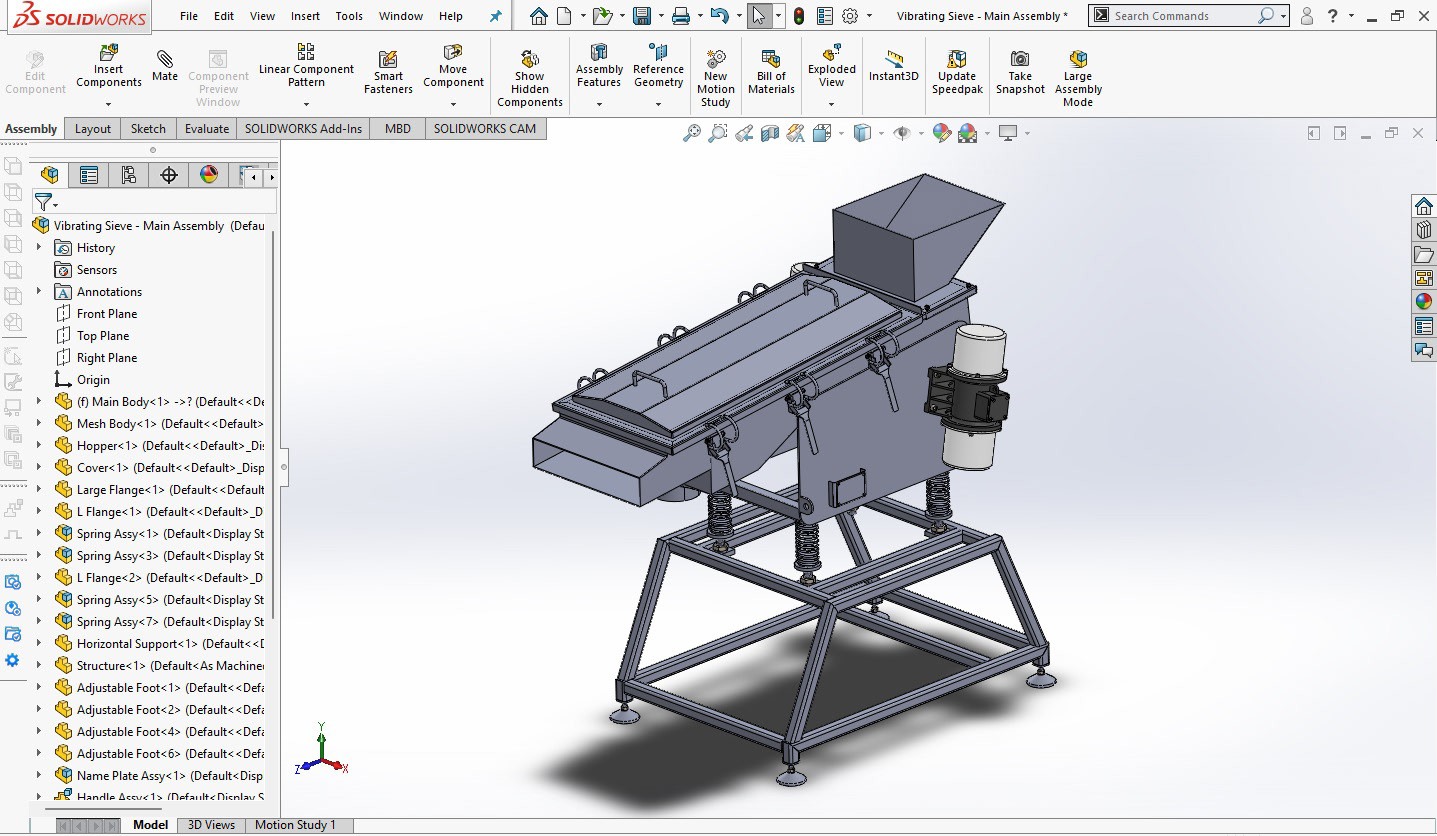

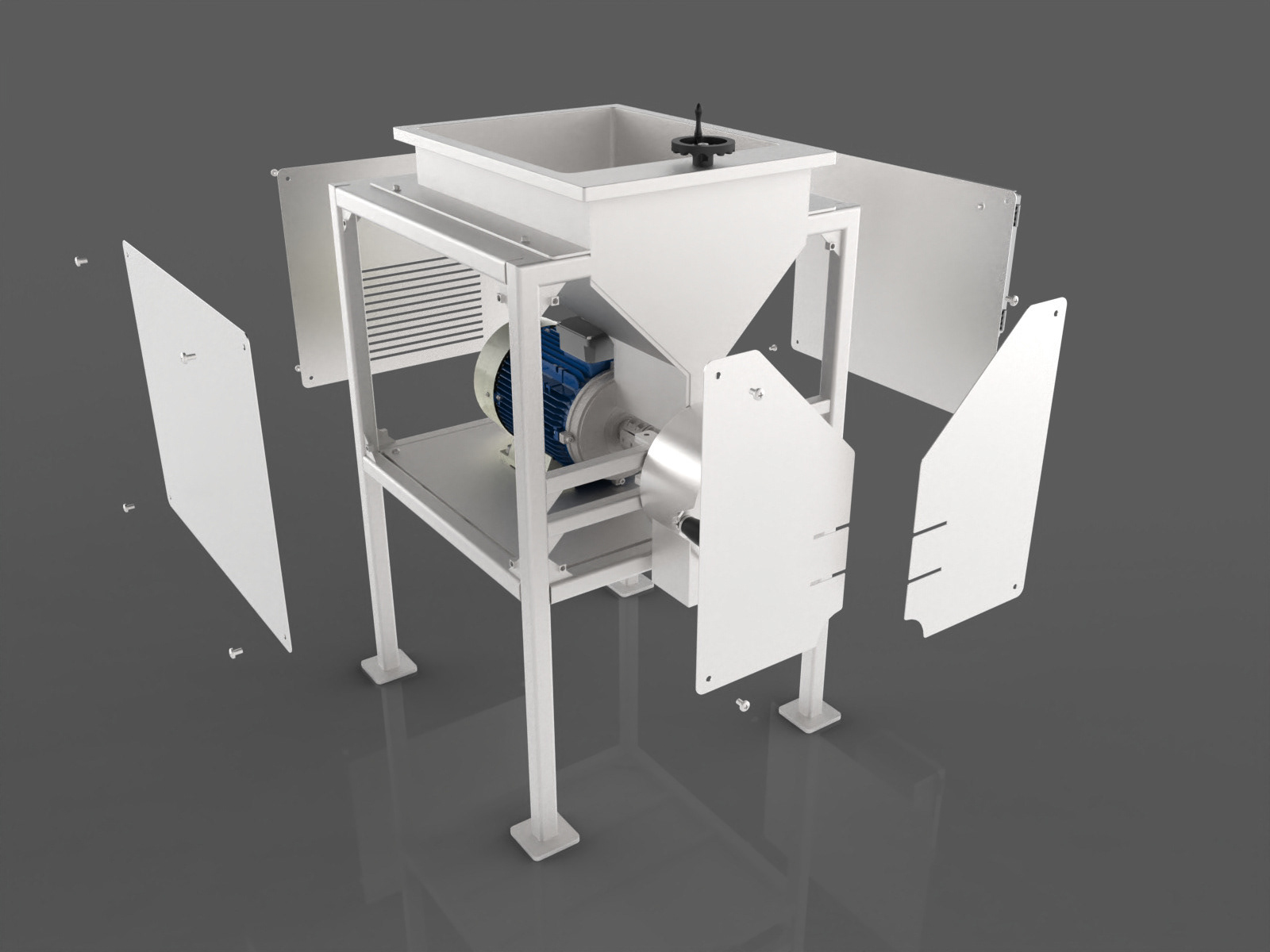

The system consists of a main body supported by a base structure with spring suspension, removable mesh body, inlet hopper and a top cover with handles and snap locks. Vibrating motors attached to the main body cause the system to oscillate on the suspension springs yielding a translation of products entering the hopper while dust and debris fall down through the mesh body (screen) and the opening at the bottom of the main body to be collected.

This reverse engineering project aims to replicate a Vibrating Sieve located upstream of the coating process in a snacks production line in order to use the replica to remove unwanted debris or product powder caused by conveying means before packaging.

System Overview

Project Objective

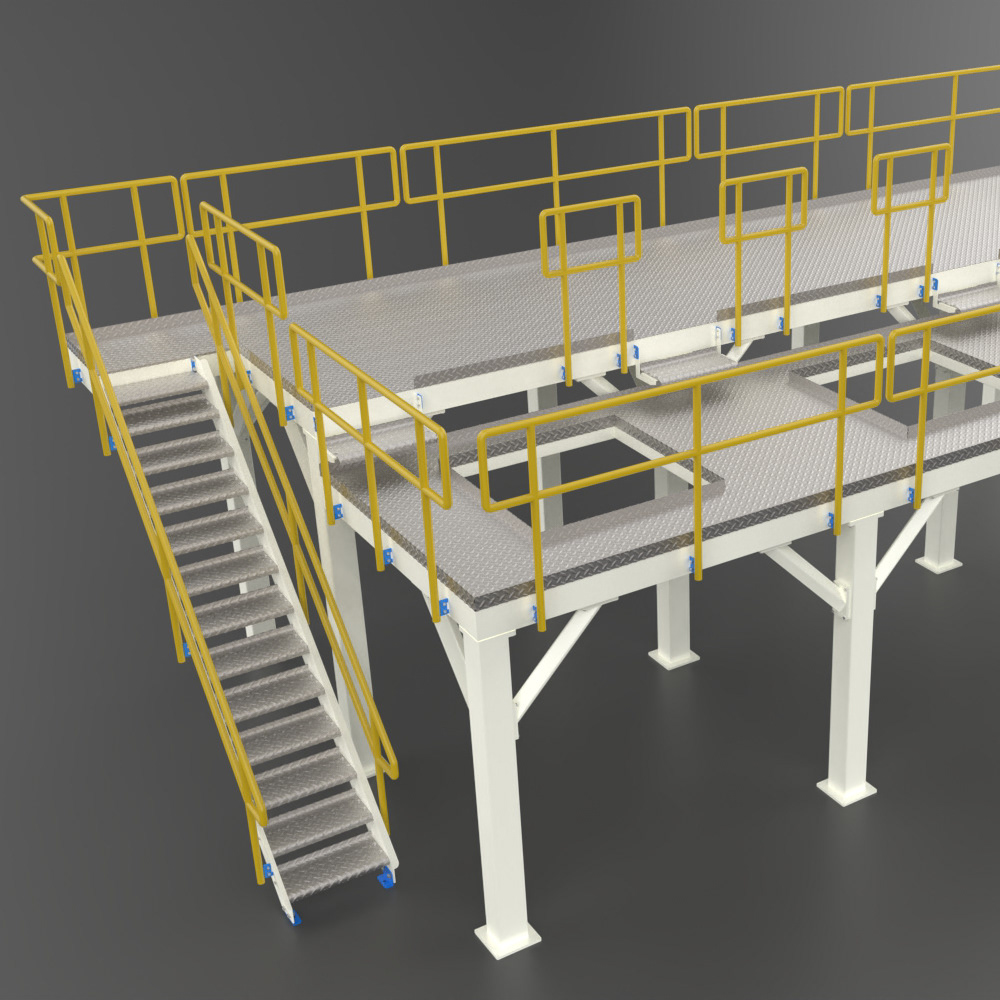

The objective is to locally replicate the system by making several units operating in the products conveying sections prior to the packaging stages as well as in many different secondary areas like raw material warehouses.

This project is intended to be part of a wide strategy to generally reduce dust buildup yielding to a safer and cleaner environment in the manufacturing plant.

This project is intended to be part of a wide strategy to generally reduce dust buildup yielding to a safer and cleaner environment in the manufacturing plant.

Design Process

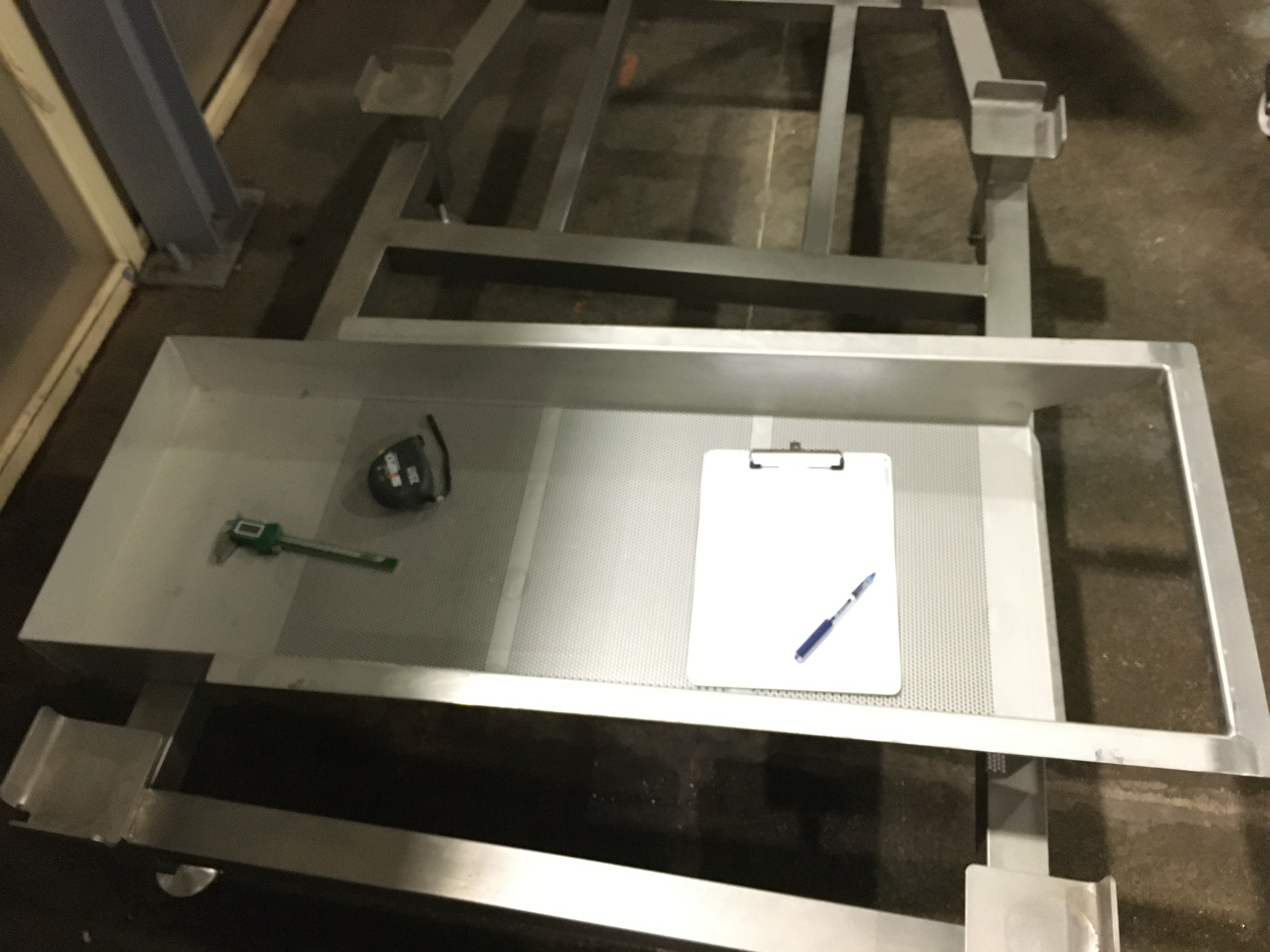

The reverse engineering process started by measuring every detail in the existing system and then reproducing it in 3D modeling & assembling using SOLIDWORKS. The first stage is a draft modeling & assembling for basic parts, while in the second stage, drawings, 3D models and assembled systems were customized following customer's requirements.

Materials used in manufactured parts are food grade stainless steel 316 & stainless steel 304.

Market available used components are:

1. Vibrating motors.

2. Suspension springs.

3. Cover snap locks (Nickel-Chrome alloy material).

4. Adjustable leveling feet.

5. Fasteners.

1. Vibrating motors.

2. Suspension springs.

3. Cover snap locks (Nickel-Chrome alloy material).

4. Adjustable leveling feet.

5. Fasteners.

3D Modeling: all parts in the assembly were modeled using SOLIDWORKS except for the vibrating motors. Motors were acquired from readily available online 3D models.

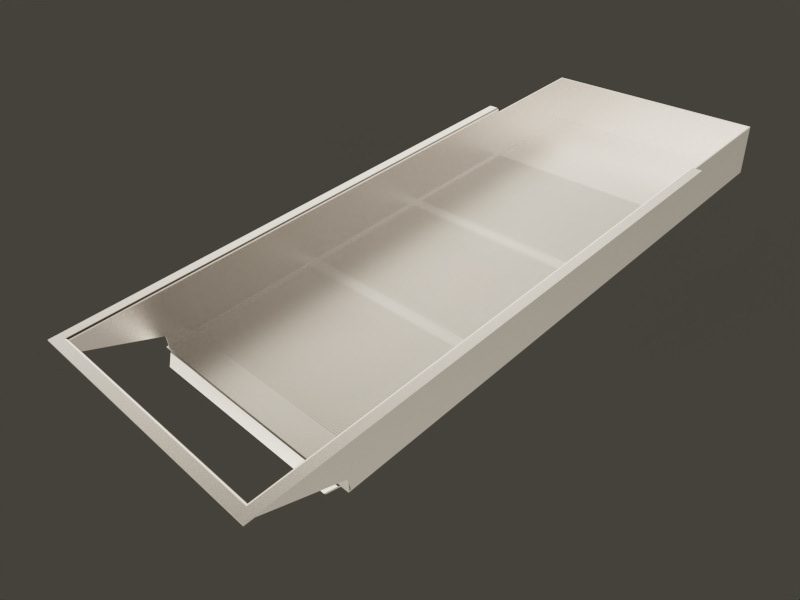

Main Body

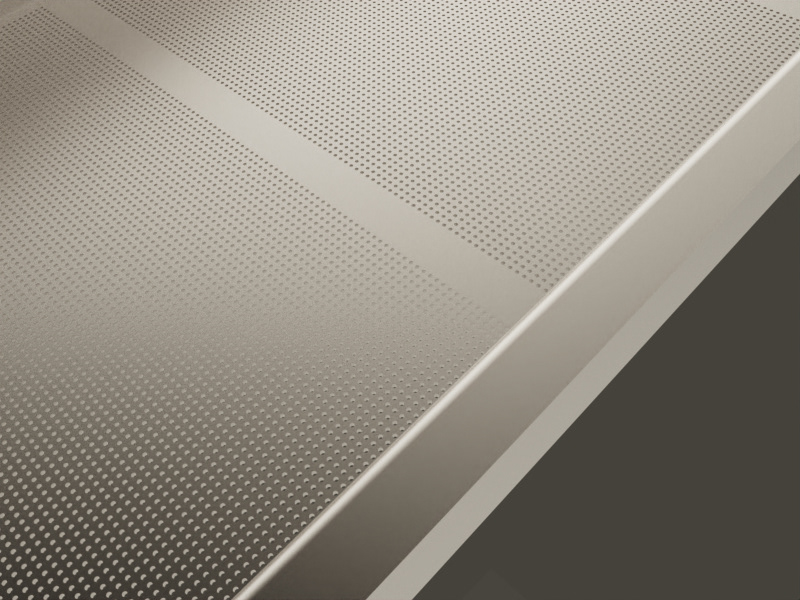

Mesh Body (Screen) 1

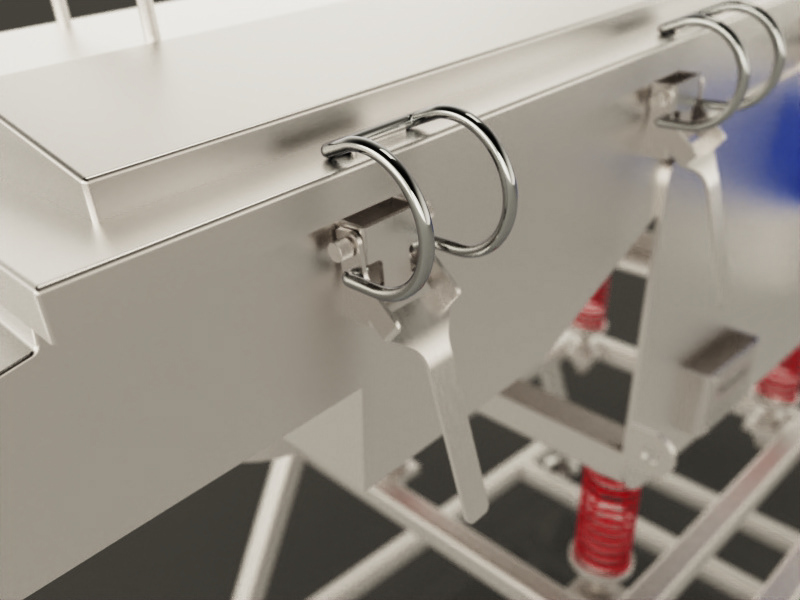

Handles & Snap Locks

Mesh Body (Screen) 2

Vibrating Sieve - Product Video

Important Notice

The original design is a property of the original equipment manufacturer (OEM). There is no intention behind this project to commercially produce or sell the products or the designs.

All published drawings, renders and animations are properties of owners, developers or OEM and were published for professional record only.

Design files or renders shall not be distributed or used under any circumstances.

Existing Vibrating Sieve 1

Existing Vibrating Sieve 2

Existing Vibrating Sieve 3

Existing Vibrating Sieve 4